Sterilization is a fundamental process in various industries, particularly in healthcare and pharmaceuticals, where the cleanliness and safety of medical devices, equipment, and consumables are of utmost importance. Among the several sterilization techniques available, Ethylene Oxide (EO) Sterilization, Steam Sterilization, and Radiation Sterilization are the most commonly employed methods. However, when comparing these methods, Ethylene Oxide stands out as the most versatile and effective solution, especially when considering heat-sensitive and delicate materials that other methods may not be suitable for.

This article will delve into the strengths of Ethylene Oxide (EO) Sterilization, comparing it to Steam and Radiation Sterilization while highlighting the advantages of EO for certain applications.

What is Ethylene Oxide Sterilization?

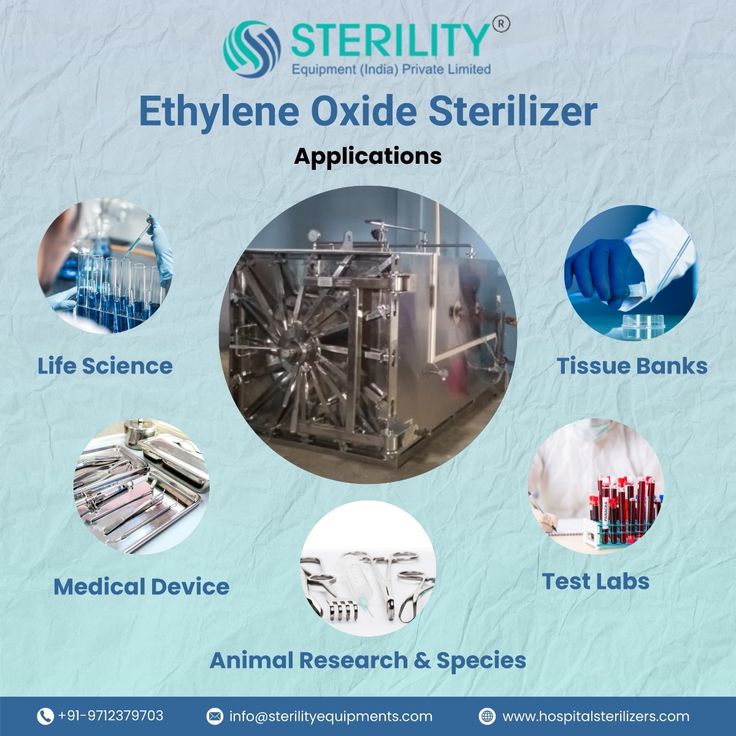

Ethylene Oxide sterilization is a gas-phase sterilization method that uses ethylene oxide gas to sterilize medical devices and instruments. It is widely used for sterilizing heat-sensitive and delicate materials that cannot withstand the high temperatures and moisture involved in steam sterilization. Ethylene oxide has become a preferred method for medical devices such as endoscopes, catheters, and electronics, where maintaining the integrity of the material is crucial.

How It Works:

- EO gas penetrates packaging and materials to reach microorganisms, killing bacteria, viruses, fungi, and spores by disrupting their DNA.

- This process typically operates at low temperatures (30-60°C), making it suitable for sterilizing items that would be damaged by heat or moisture.

- After the sterilization cycle, the EO gas is removed, and the items undergo an aeration process to eliminate any residual gas, ensuring safety for humans.

Key Characteristics:

- Low temperature: Does not degrade heat-sensitive materials.

- Penetrates packaging: Can sterilize items in their packaging, which reduces handling and maintains sterility.

- Flexible cycle time: Although the process takes several hours, it is ideal for items that require gentler handling.

Steam Sterilization (Autoclaving)

Steam sterilization, also known as autoclaving, is a high-temperature sterilization method that uses saturated steam under pressure to sterilize medical instruments. It is one of the most commonly used sterilization methods due to its speed and simplicity. However, when compared to Ethylene Oxide, steam sterilization has certain limitations.

How It Works:

- Steam sterilization uses high-pressure steam (typically between 121°C to 134°C) to kill microorganisms. The process involves heating the items to high temperatures, which can cause damage to heat-sensitive materials.

- Steam sterilization works well for durable instruments like scalpels, surgical tools, and gowns but is unsuitable for items that cannot tolerate high temperatures or moisture.

Limitations Compared to EO Sterilization:

- Heat Sensitivity: Steam sterilization can cause damage to delicate instruments and materials such as plastics, rubbers, and electronics. These items may degrade or warp under the high temperatures and moisture.

- Limited Penetration: The steam sterilization process does not effectively penetrate packaging, which can limit its ability to sterilize pre-packaged items. This may also result in potential handling issues for the hospital staff.

Radiation Sterilization

Radiation sterilization uses ionizing radiation (gamma or electron beam radiation) to sterilize medical devices, pharmaceuticals, and food products. It is effective for sterilizing pre-packaged products and disposable items, but it has its own set of limitations when compared to Ethylene Oxide.

How It Works:

- Gamma radiation uses cobalt-60 or cesium-137 to emit gamma rays, which penetrate materials and destroy microorganisms at the DNA level.

- Electron beam (e-beam) radiation involves the use of high-energy electrons to kill microorganisms by disrupting their DNA. However, this method has a more limited penetration depth compared to gamma radiation.

Limitations Compared to EO Sterilization:

- Specialized Equipment and Facilities: Radiation sterilization requires specialized equipment and radiation facilities. These can be costly to set up and maintain, making this method more suitable for high-volume applications rather than small-scale sterilization.

- Handling and Packaging: Unlike EO, which can sterilize items within their packaging, radiation sterilization is limited in the types of packaging materials it can sterilize. Materials like plastics and polymers can be affected by radiation, resulting in physical changes such as brittleness or degradation.

Other Limitations:

- Slower Process (Gamma Radiation): Gamma radiation sterilization can take several days to process large batches, making it less ideal for environments that require quicker turnaround times, like hospitals and clinics.

- Costly Infrastructure: Setting up and maintaining radiation sterilization facilities is expensive, making it a less feasible option for smaller medical facilities or those with a lower volume of sterilization needs.

Why Ethylene Oxide Sterilization is the Preferred Choice?

Compatibility with Heat-Sensitive Materials

One of the most significant advantages of EO sterilization is its ability to sterilize heat-sensitive materials. Many medical devices and instruments, such as plastic components, electronic devices, and rubber parts, cannot tolerate the high temperatures required by steam sterilization. EO sterilization operates at low temperatures (30-60°C), making it ideal for delicate and temperature-sensitive items.

In comparison, steam sterilization can damage these materials by causing them to melt, warp, or degrade, while radiation sterilization may cause brittleness or other physical changes in plastics, limiting its use for certain items.

Penetration of Packaging

Another advantage of EO sterilization is its ability to penetrate packaging materials. Ethylene oxide gas can easily infiltrate through various types of packaging to sterilize items inside, ensuring that the sterility of the item is maintained until it is ready for use. This is particularly important in the hospital environment, where pre-packaged sterile items are common.

While steam sterilization may not effectively sterilize materials within their packaging, and radiation sterilization can be limited by the type of packaging used, EO sterilization ensures that the sterility of the product is not compromised.

Longer Shelf Life for Sterilized Items

Since EO sterilization is done at low temperatures and does not rely on moisture, it does not cause the corrosion or rusting that can occur with steam sterilization. This helps maintain the integrity of metal tools and ensures that sterilized items remain in optimal condition over time. Radiation sterilization also avoids this issue, but EO is often preferred when dealing with complex instruments or items that require long-term storage.

Efficiency for Diverse Applications

EO sterilization is versatile and can be used to sterilize a wide range of materials, including plastics, metals, rubber, and electronics, making it ideal for medical devices, surgical tools, wound care products, and more. Unlike steam sterilization, which is limited to heat-resistant items, EO can handle a broader spectrum of materials without damaging them.

Additionally, unlike radiation sterilization, which is typically limited to certain packaging and materials, EO sterilization offers more flexibility, especially in hospitals that require sterilization for a diverse array of instruments and packaging types.

Faster Turnaround Times Compared to Radiation

Although EO sterilization typically takes several hours, it can be much quicker compared to radiation sterilization methods like gamma radiation, which can take days to complete large-scale sterilization cycles. This makes EO a more practical option for hospitals or clinics that need a steady supply of sterile instruments.

Conclusion

While steam sterilization and radiation sterilization each have their advantages, Ethylene Oxide (EO) sterilization stands out as the preferred method for sterilizing heat-sensitive materials, offering a flexible, efficient, and safe solution for the healthcare industry. It is the ideal choice for sterilizing delicate medical devices, electronic components, and plastic instruments that cannot withstand the harsh conditions of other methods. EO sterilization’s ability to penetrate packaging, prevent corrosion, and sterilize a wide range of materials makes it a versatile and reliable option.

In contrast to steam sterilization, which is limited to heat-resistant items, and radiation sterilization, which requires specialized equipment and facilities, Ethylene Oxide provides optimal safety, cost-effectiveness, and efficiency for medical professionals looking to maintain the highest standards of sterility without compromising the integrity of their equipment.