Medical ETO Sterilizer in Andhra Pradesh Hospitals and Teaching Institutes

Ethylene Oxide Sterilization: The Pillar of Modern Healthcare in Andhra Pradesh

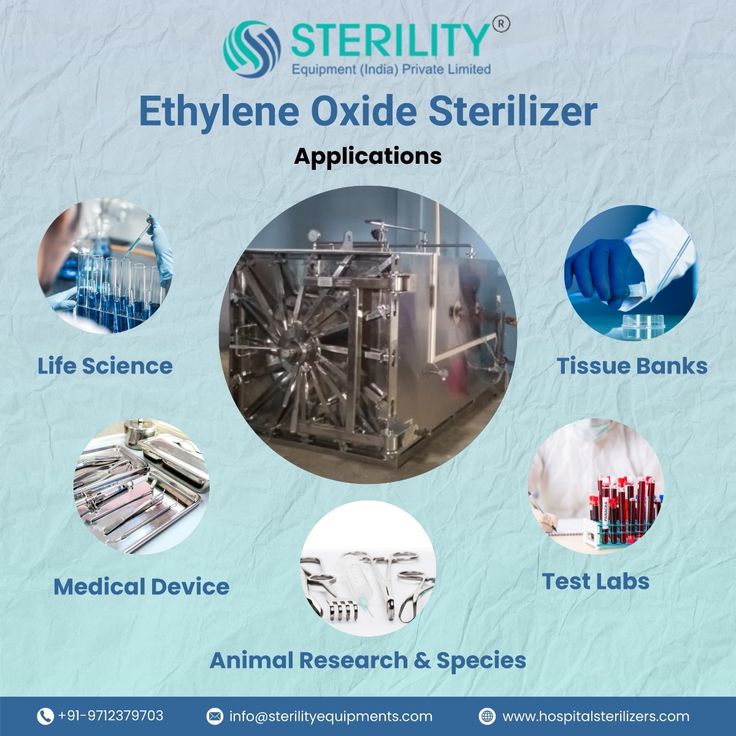

In the rapidly advancing medical landscape of Andhra Pradesh, Ethylene Oxide Sterilization has emerged as a non-negotiable standard for patient safety. Modern hospitals and medical colleges are no longer just centers of care; they are hubs of advanced surgical intervention where high-precision, heat-sensitive instruments are the norm. Medical sterilization is the first line of defense against Hospital-Acquired Infections (HAIs), ensuring that every tool used in a clinical environment is free from microbial life.

Many of today’s most critical surgical tools – such as endoscopes, catheters and cardiac stents – are made of specialized polymers and electronics that cannot withstand the high temperatures of traditional steam autoclaving. This is why a medical sterilizer machine utilizing ETO gas is essential. It provides a low-temperature chemical process that penetrates complex geometries without damaging the integrity of the device, effectively bridging the gap between advanced medical technology and rigorous safety protocols.

Medical Device Sterilization Demand: Analyzing AP’s Healthcare Infrastructure

Andhra Pradesh is witnessing an unprecedented expansion in both public and private healthcare sectors. The growth of multispecialty hospitals in major hubs has led to a direct spike in the demand for medical device sterilization solutions. As the state government continues to upgrade district hospitals and establish new teaching institutes, the infrastructure for medical devices sterilization must keep pace.

A key component of this growth is the modernization of Central Sterile Supply Departments (CSSD). These departments act as the “heart” of the hospital, where every hospital instrument sterilizer system must operate with 100% reliability. With the state aiming to become a healthcare destination in Southern India, the integration of high-capacity ETO units is vital for maintaining international accreditation standards.

City-Wise Demand for Medical ETO Sterilizer in Andhra Pradesh

Visakhapatnam: Ethylene Oxide Sterilization for Tertiary Care Needs

As the executive capital and a major medical hub, Visakhapatnam hosts some of the state’s largest healthcare facilities, including the historic Andhra Medical College. The high surgical volume in Vizag’s tertiary care centers is a primary driver for the sterilisation of surgical instruments. With an increasing number of robotic surgeries and neuro-interventions, the adoption of ethylene oxide sterilization is mandatory for protecting expensive, delicate equipment. Teaching hospitals here are also scaling up their medical sterilization systems to cater to both massive patient inflows and student training requirements.

Vijayawada: Sterilization in Operation Theatre and Surgical Growth

Vijayawada has seen a surge in multi-specialty hospitals that focus on cardiac and orthopedic excellence. These facilities are heavily investing in sterilization in operation theatre solutions to minimize the risk of post-operative complications. The requirement for a reliable medical sterilizer machine is particularly high in surgical departments that handle a high turnover of laparoscopic tools. Furthermore, local medical colleges are emphasizing the sterilisation of medical devices as a core part of their clinical compliance training.

Guntur: Medical Device Sterilization in Academic Centers

Guntur is recognized for its robust medical education ecosystem. Teaching hospitals in the region depend on medical device sterilization to maintain the safety of reusable instruments used by hundreds of residents and interns daily. The hospital instrument sterilizer units in these academic settings are workhorses, running multiple cycles to keep up with the demand. There is a growing trend of integrating Sterility Medical Device standards directly into the curriculum, ensuring that the next generation of doctors understands the mechanics of ETO safety.

Testimonial

“I did buy a 50 litre ETO sterilizer from Mr Alex, three years ago for Sun Orthopaedic Hospital, Bangalore. I am extremely happy with the service and performance of the machine. Also the running cost of the machine is extremely low.“

Tirupati: Sterilization Benefits for Expanding Healthcare Hubs

Tirupati serves as a major referral point for patients from Rayalaseema and neighboring states. This massive patient inflow has forced a focus on the sterilization benefits offered by ETO, particularly for non-heat-resistant tools used in ophthalmology and cardiology. The demand for a modern sterilizer machine in Tirupati is driven by the need for quick turnaround times without compromising the delicate optics of specialized surgical gear.

Nellore: Medical Sterilizer Machine Adoption in Secondary Care

In Nellore, district hospitals and private clinics are rapidly adopting the medical sterilizer machine to elevate their emergency care standards. The need for reliable sterilisation of surgical instruments is critical here, given the city’s role in handling trauma cases. Furthermore, many facilities are now utilizing the Sterilization Roll for safe packaging post-ETO cycles, ensuring that instruments remain sterile until the exact moment of use in the OT.

Kurnool, Rajahmundry and Anantapur: Regional Sterilization Solutions

Regional hospitals in Kurnool and Rajahmundry are no longer lagging behind their metropolitan counterparts. These cities are seeing a steady increase in the reliance on ethylene oxide sterilization for specialty departments like Urology and Gastroenterology. As the government expands the “Nadu-Nedu” health initiative, the hospital instrument sterilizer is becoming a standard feature in newly renovated government medical colleges across Anantapur and beyond.

Sterilization Process for Medical Devices: Key Demand Drivers

The primary driver for ETO demand in Andhra Pradesh is the shift toward complex, minimally invasive surgeries. Each of these procedures requires a specialized sterilization process for medical devices that protects lenses, fibers and sensors.

Moreover, national and international accreditation (like NABH) has pushed sterilization in operation theatre standards to new heights. Hospital administrators are now more aware of the long-term sterilization benefits, understanding that investing in high-quality ETO equipment reduces the “cost of poor quality” associated with infections and equipment damage.

Sterilization Medical Devices: Applications in Pharmaceutics

Beyond the operating table, sterilization medical devices are essential in the pharmaceutical sector, particularly for drug-delivery tools and pre-filled syringes. Andhra Pradesh’s growing pharma belt uses sterilization pharmaceutics to ensure that delivery mechanisms are contaminant-free. Adhering to Sterility Medical Device safety benchmarks is critical for companies looking to export medical products from the state to global markets.

Challenges in ETO Implementation: How Sterility Equipment (India) Pvt. Ltd. Helps

Implementing an ETO system comes with challenges:

- Infrastructure: ETO requires specialized ventilation and gas handling.

- Safety Protocols: Handling ethylene oxide sterilization requires precision to ensure zero gas leakage.

- Skilled Manpower: Operating a medical sterilization unit requires trained technicians.

Sterility Equipment (India) Pvt. Ltd. addresses these hurdles by providing end-to-end solutions. They offer advanced, fully automated ETO sterilizers that simplify the user interface, making it easier for hospital staff to manage cycles. Their equipment is designed with multi-level safety sensors to mitigate gas risks and they provide comprehensive training to local hospital teams in Andhra Pradesh, ensuring that the sterilization equipment market continues to grow safely and efficiently.

Sterilization Equipment Market: Future Trends in Andhra Pradesh

The sterilization equipment market in Andhra Pradesh is poised for a decade of growth. While Tier-1 cities like Vizag and Vijayawada currently lead the demand for the medical sterilizer machine, the future scope lies in Tier-2 and Tier-3 cities. As secondary care hospitals upgrade their facilities, the shift from basic boiling or chemical dipping to professional medical device sterilization will be the defining trend of the late 2020s.

Conclusion: The Future of Ethylene Oxide Sterilization in AP

From Visakhapatnam to Tirupati, the demand for ethylene oxide sterilization is a reflection of Andhra Pradesh’s commitment to world-class healthcare. The long-term importance of medical sterilization cannot be overstated; it is the silent guardian of patient health. As hospitals continue to invest in a high-quality medical sterilizer machine, the state will solidify its position as a leader in safe, advanced and reliable medical care.